Email:overseas@hwforgings.com

Email:overseas@hwforgings.com

QUALITY

For good brand products, the control of raw materials is particularly important. When purchasing raw materials, we strictly follow the our technical requirements and select qualified and high-quality raw materials provided by the suppliers who have production technology qualifications. The purchased raw materials were all subjected to 100% chemical composition testing and surface quality testing, and were tested and accepted according to the company's technical requirements and relevant national technical standards. Advanced testing equipment and reliable quality assurance system ensure that raw materials meet the accuracy and reliability of product standards.

From the beginning of the product labeling with the whole process of product manufacturing to track the transplant. The products can be traced back to the product from the smelting furnace number, heat treatment batch number and the performance test data and other important information.

Through cooperation with scientific research institutes, the Deform-3D simulation software is combined with Solidworks 3D modeling software and AutoCAD drawing software. For complex forgings or new materials, on the basis of numerical simulation, forming process and advance understanding of the rationality of the material after the preparation of forging heating, forging and heat treatment after forging process, can effectively reduce the material loss, improve production efficiency and ensure product manufacturing process scientific and reasonable budget. At present, a number of invention patents and utility model patents have been obtained.

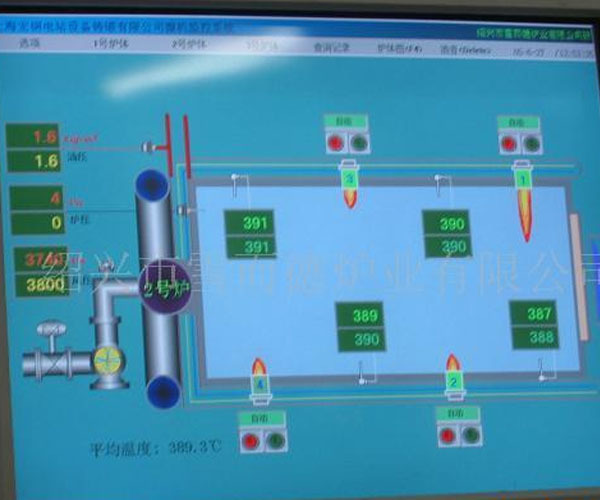

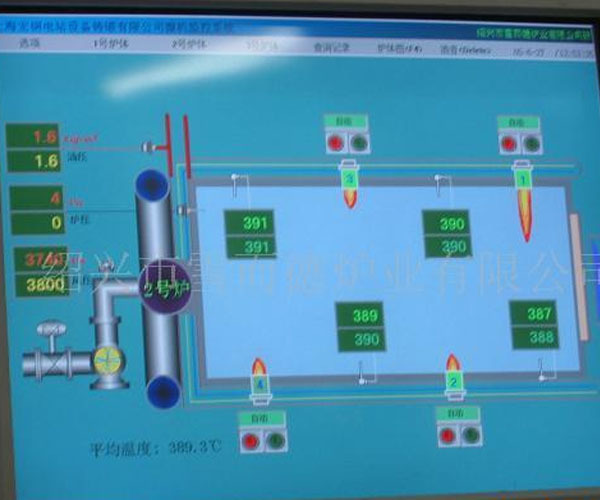

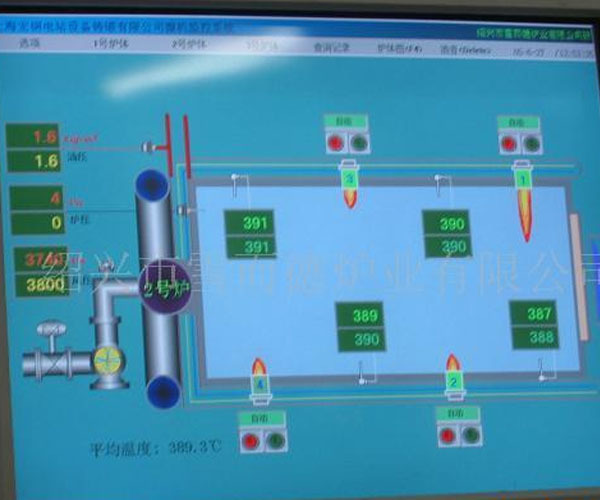

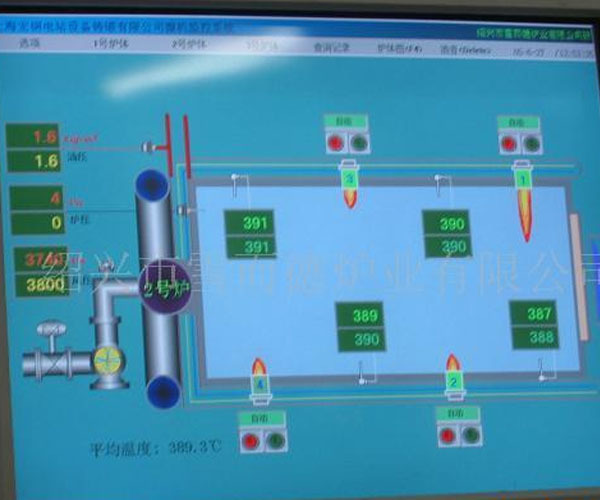

Forging blank using natural gas heating furnace automatic control of the most advanced regenerative heating furnace temperature of natural gas, heating furnace is controlled by a computer program, which can be in strict accordance with the process of heating billet heating curve has been developed. And in the set temperature and time range of insulation.

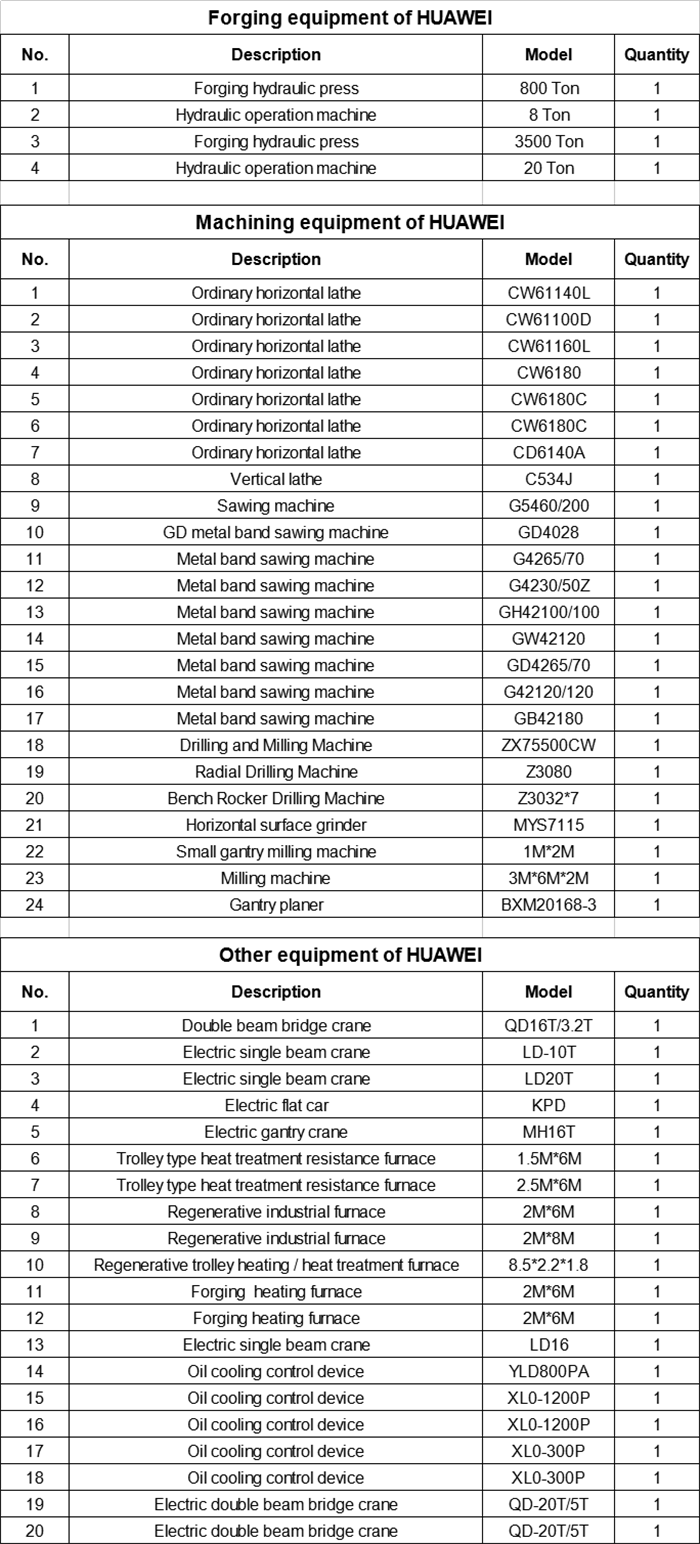

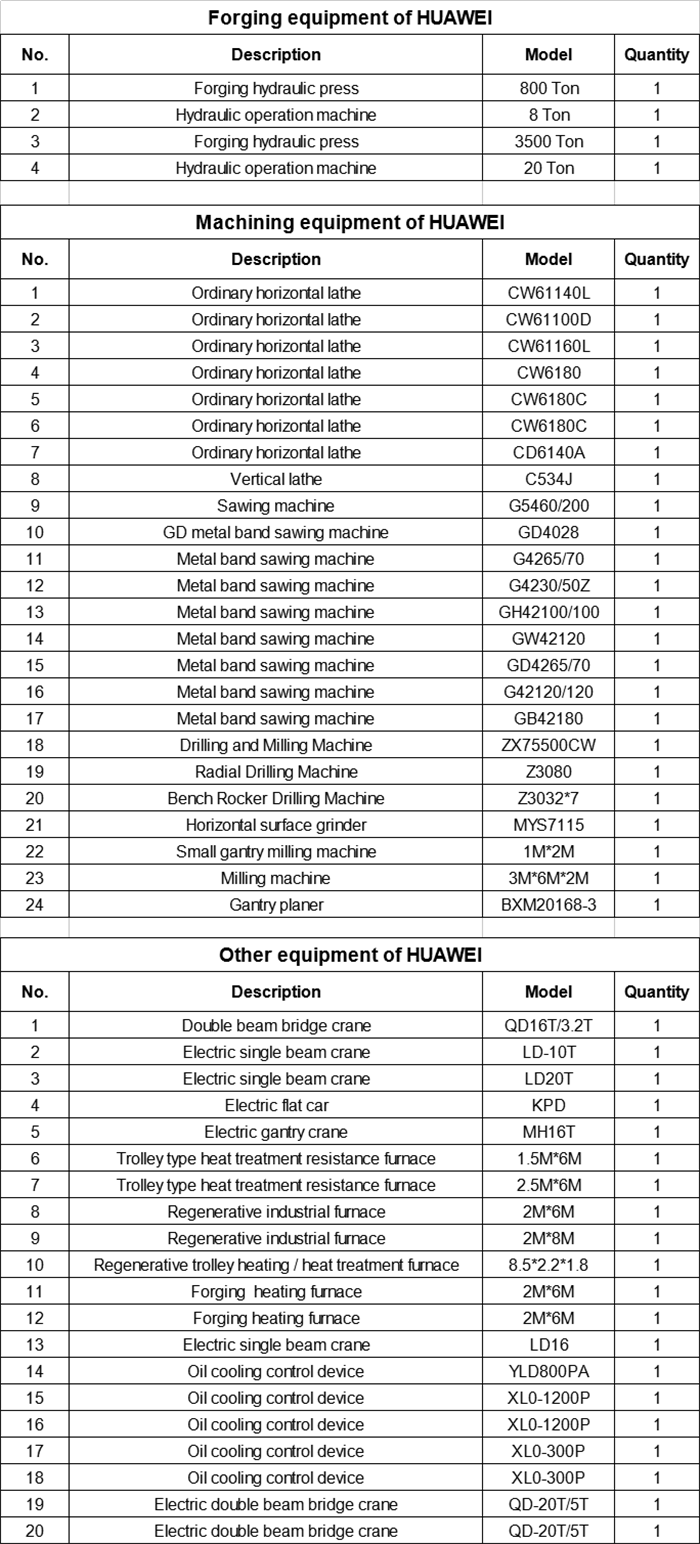

Forging equipment 3500t, 800t two sets of free forging hydraulic unit. According to the quality requirements of different products, choose different forging forging equipment, scientific and reasonable deformation process and forging ratio and temperature field, the center of the forgings, forging organization dense, to ensure the internal quality of forgings.

The company's advanced high-power trolley type heat treatment special resistance furnace and the company's advanced science and technology after the heat treatment process, quenching and tempering heat treatment process to ensure that the product's internal metallurgical structure and mechanical properties of the product requirements. The programmable logic controller of resistance furnace controls the process of heat treatment and heat preservation of each heat treatment furnace according to the heat treatment process curve compiled by the software. All kinds of special steel forging normalizing annealing (N), (A) or solid solution (S) after heat treatment, grain refinement, effectively improve the comprehensive performance. The normalized and tempered (N+T), and (Q+T) and austenitic stainless steel solid solution properties such as heat treatment, ensure the performance requirements of different products.

Fully equipped vehicles, milling, drilling, planing machine processing equipment, advanced processing technology and processing technology can provide customers with quality and quantity of product processing services.

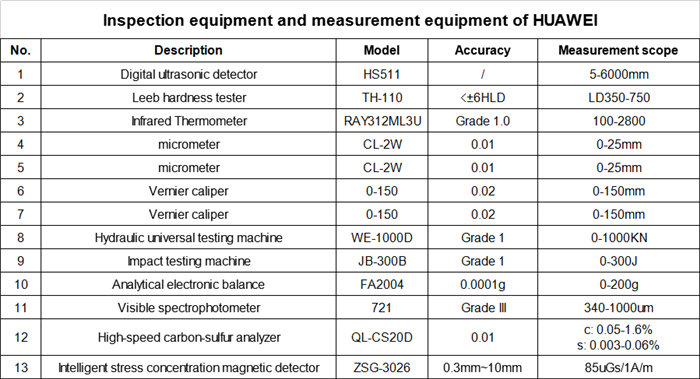

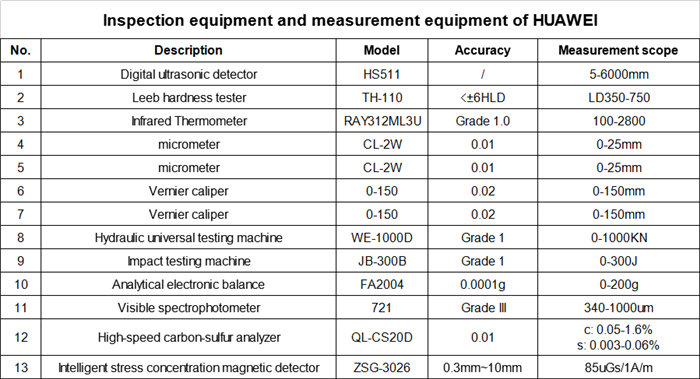

Mechanical properties, metallographic test equipment complete, test personnel can according to different senior international test standard for compliance with its technical requirements of forging products such as materials tensile and impact properties of accurate data and non metallic inclusions and grain size microstructure analysis.

High resolution and high power digital display ultrasonic flaw detector, magnetic detection equipment and has a senior qualification inspection technicians, according to the different domestic and foreign standard detection method and customer product quality and technical requirements, equipped with the world's most advanced residual stress and fatigue point detector can accurately detect whether the workpiece a residual stress exists in every process link. Able to accurately prevent accidents in the use of the workpiece. The nondestructive testing and surface magnetic particle testing can be used to detect the internal microstructure and surface micro defects of the forgings, and ensure the internal quality and surface quality of the products meet the needs of the customers.

The company has a reliable product quality assurance management system, the company has passed ISO9001:2015 quality management system certification, API (American Petroleum Institute) Q1&20B system and product certification, ABS (ABS) product certification system, in strict accordance with the ISO9001:2015 and API Q1, have reached the standard of quality management system requirements.

EQUIPMENT

PROCESS FLOWCHART

For good brand products, the control of raw materials is particularly important. When purchasing raw materials, we strictly follow the our technical requirements and select qualified and high-quality raw materials provided by the suppliers who have production technology qualifications. The purchased raw materials were all subjected to 100% chemical composition testing and surface quality testing, and were tested and accepted according to the company's technical requirements and relevant national technical standards. Advanced testing equipment and reliable quality assurance system ensure that raw materials meet the accuracy and reliability of product standards.

From the beginning of the product labeling with the whole process of product manufacturing to track the transplant. The products can be traced back to the product from the smelting furnace number, heat treatment batch number and the performance test data and other important information.

Through cooperation with scientific research institutes, the Deform-3D simulation software is combined with Solidworks 3D modeling software and AutoCAD drawing software. For complex forgings or new materials, on the basis of numerical simulation, forming process and advance understanding of the rationality of the material after the preparation of forging heating, forging and heat treatment after forging process, can effectively reduce the material loss, improve production efficiency and ensure product manufacturing process scientific and reasonable budget. At present, a number of invention patents and utility model patents have been obtained.

Forging blank using natural gas heating furnace automatic control of the most advanced regenerative heating furnace temperature of natural gas, heating furnace is controlled by a computer program, which can be in strict accordance with the process of heating billet heating curve has been developed. And in the set temperature and time range of insulation.

Forging equipment 3500t, 800t two sets of free forging hydraulic unit. According to the quality requirements of different products, choose different forging forging equipment, scientific and reasonable deformation process and forging ratio and temperature field, the center of the forgings, forging organization dense, to ensure the internal quality of forgings.

The company's advanced high-power trolley type heat treatment special resistance furnace and the company's advanced science and technology after the heat treatment process, quenching and tempering heat treatment process to ensure that the product's internal metallurgical structure and mechanical properties of the product requirements. The programmable logic controller of resistance furnace controls the process of heat treatment and heat preservation of each heat treatment furnace according to the heat treatment process curve compiled by the software. All kinds of special steel forging normalizing annealing (N), (A) or solid solution (S) after heat treatment, grain refinement, effectively improve the comprehensive performance. The normalized and tempered (N+T), and (Q+T) and austenitic stainless steel solid solution properties such as heat treatment, ensure the performance requirements of different products.

Fully equipped vehicles, milling, drilling, planing machine processing equipment, advanced processing technology and processing technology can provide customers with quality and quantity of product processing services.

Mechanical properties, metallographic test equipment complete, test personnel can according to different senior international test standard for compliance with its technical requirements of forging products such as materials tensile and impact properties of accurate data and non metallic inclusions and grain size microstructure analysis.

High resolution and high power digital display ultrasonic flaw detector, magnetic detection equipment and has a senior qualification inspection technicians, according to the different domestic and foreign standard detection method and customer product quality and technical requirements, equipped with the world's most advanced residual stress and fatigue point detector can accurately detect whether the workpiece a residual stress exists in every process link. Able to accurately prevent accidents in the use of the workpiece. The nondestructive testing and surface magnetic particle testing can be used to detect the internal microstructure and surface micro defects of the forgings, and ensure the internal quality and surface quality of the products meet the needs of the customers.

The company has a reliable product quality assurance management system, the company has passed ISO9001:2015 quality management system certification, API (American Petroleum Institute) Q1&20B system and product certification, ABS (ABS) product certification system, in strict accordance with the ISO9001:2015 and API Q1, have reached the standard of quality management system requirements.

EQUIPMENT

PROCESS FLOWCHART

Tel:+86-29-84312835

Tel:+86-29-84312835 Language

Language